Quality Inspection

for Siemens NX

Close the gap between design and quality.

neoapps | Products

With the modules of the inspection report suite, you automate the creation of first article inspection reports based on CAD data in Siemens NX format. This saves you up to 90% time when creating test documents such as initial sampling or series testing. Test plan takes over the otherwise error-prone creation of initial sample test reports and automatically puts the stamp with the correct test numbers on all desired features such as dimensions, texts, surface specifications or GD&Ts. You can then generate perfectly positioned, error-free PPAP documents such as initial sample test reports in any format at the push of a button and export them directly to a PLM or CAQ system, for example. This closes the gap between design and quality and makes a valuable contribution to digitization in your company.

The benefits in a nutshell

More Iime Savings

The automated labeling of the test characteristics saves you up to 90% time compared to manual approaches.

.

More Automation

Establish a completely consistent process between design and quality without media discontinuity.

Better Quality

Error-free test documents reduce the reject rate and thus lead to less rework and higher quality of your products.

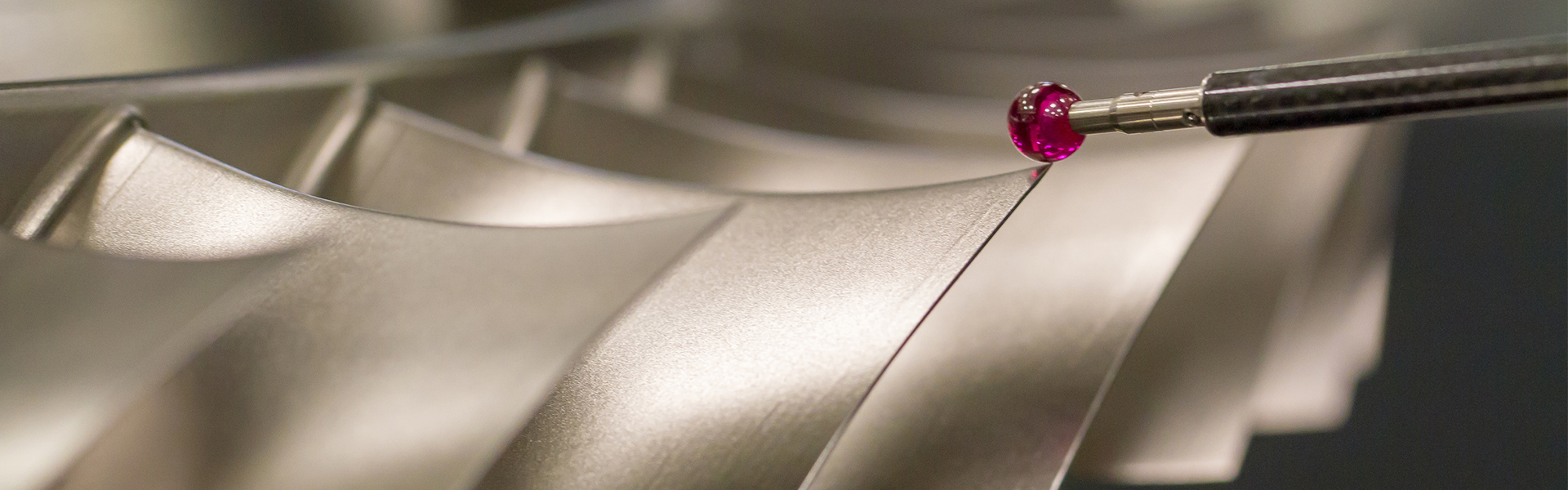

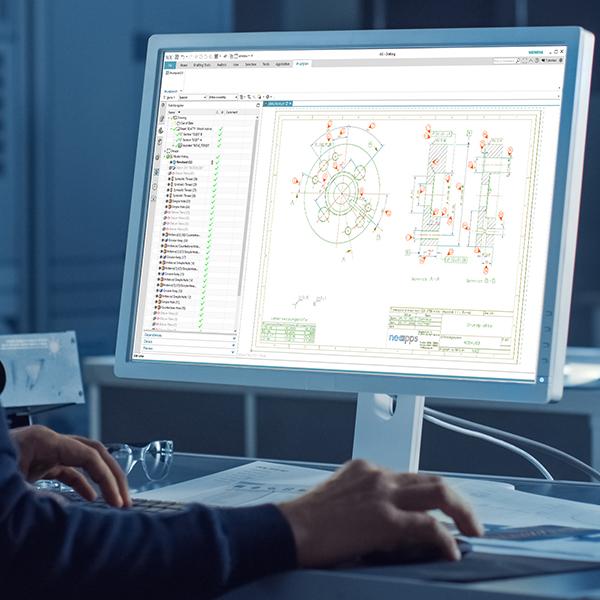

Extraction of Inspection Features from 2D, 3D or both.

Drawing-based work with 2D drawings

Mark and extract your test characteristics directly from the technical drawings in 2D format. Regardless of whether linear dimensions, GD&T, surfaces, angular dimensions, texts or symbols. At the push of a button, test stamps are placed on the drawing without colliding. The numbering scheme can be configured company-specifically. Even the position of an inspection feature within the drawing frame is recognized.

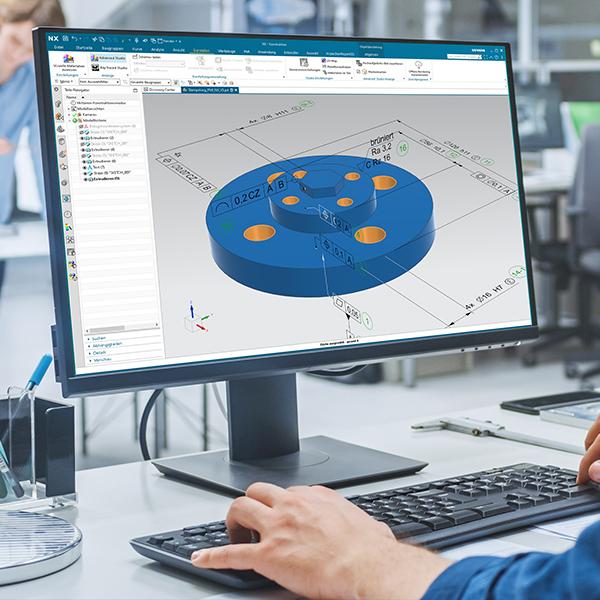

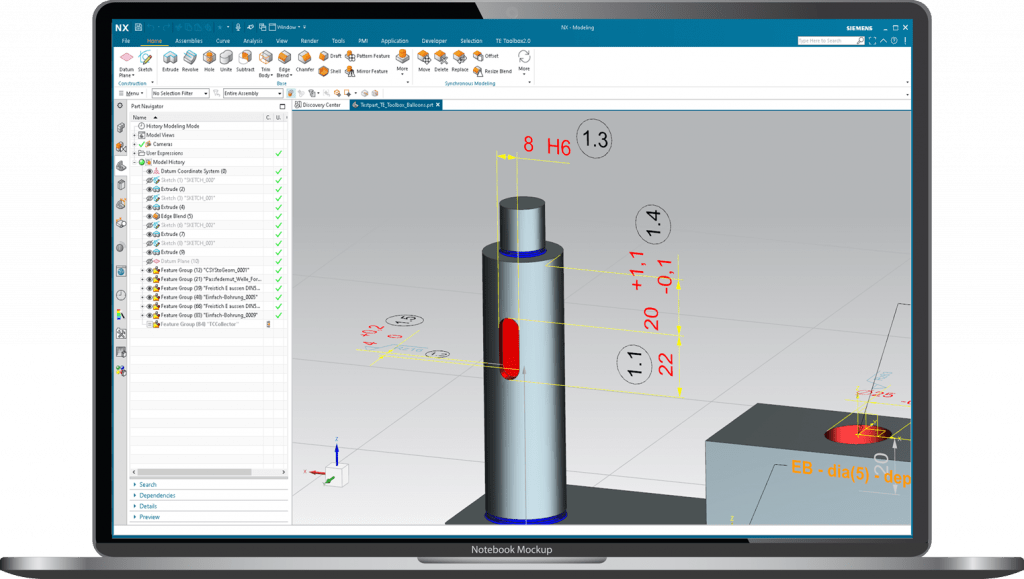

Model-based work with 3D models

In model-based design with PMI (MBD), mark and extract inspection features directly in 3D. All model views are taken into account. Multiple occurrences can also be taken into account in the context of MBD via the information of the associative objects of a characteristic (e.g. cylindrical lateral surface). This further increases the potential for automation.

With the modules of the InspectionReportSuite, you can extract inspection features from NX drawings or models fully automatically. In addition, errors in the transmission in the direction of the subsequent processes are almost impossible.

The success of 20 years in numbers

Satisfied Customers

Each customer brings new requirements and thus ensures a constant improvement of the solution.

Lines of source code

That’s how extensive the powerful library behind the solution family of the test plan suite is now. Packed with features & functions. And there are more every day.

Ballooned Features

Inspection Features have already been ballooned by our customers. Fully automatic and without transmission errors.

Workflow-based Ballooning and Extraction

Automatic identification and transfer of inspection features in batch mode.

In order to maximize the degree of automation, the modules of the test plan suite can also be operated in batch mode. This approach is ideal for integrating the identification and transfer of inspection characteristics into a workflow in a PDM system.

Revision Compare for Siemens NX

One Technology. Two Solutions. All changes at a glance.

You can also use the feature numbering system to document changes to your models or drawings. The test plan suite ensures that the characteristics are numbered consistently across versions. This makes it easy to trace changes between revision levels. All “real” changes are generated in a neutral, readable format such as PDF or 3D PDF via an additional module and managed in the PDM system. Can also be used fully automatically in the release process.

Better Communication with your Supply Chain using Technical Data Packages.

Improve communication with your supply chain by providing your suppliers with a complete data package of your assemblies and individual parts. This data package contains a list of all inspection feature, documentation of design changes, as well as the technical drawing or the 3D model in neutral formats such as Excel, JT or 3D PDF.

PDM-Integration of the InspectionReportSuite

Teamcenter from Siemens DIS

Integrated means: The extracted data can be used within the Teamcenter ecosystem. You can also integrate the batch process into various workflows on the Teamcenter Dispatcher. Data packages such as a list of characteristics in Excel or a 3D PDF must also be stored in the Teamcenter as a data set below the item revision or as an independent QS item.

SAP ECTR von DSCS AG

With SAP ECTR you can manage your design data directly in SAP. So you have everything in one system, without media breaks and unnecessary data silos. Due to the long-term partnership with DSCS AG, the modules of the InspectionReportSuite can be integrated via a standard interface. The result is a deep integration with numerous application options such as the SAP inspection plan or the production-accompanying inspection.

![]()

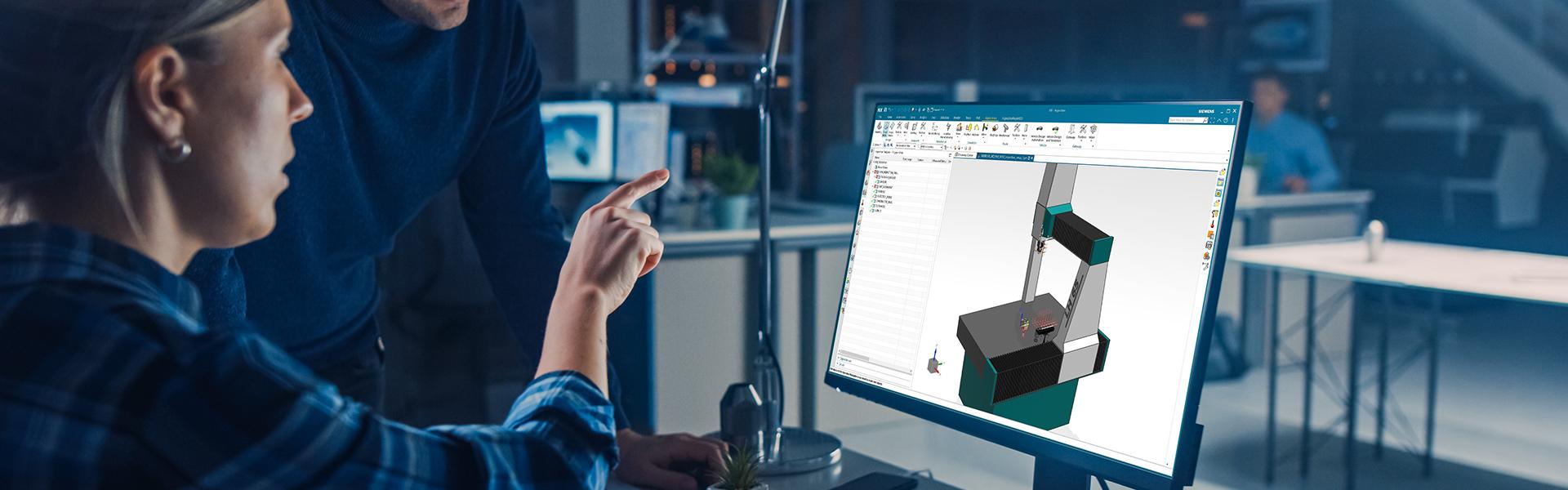

Would you like to close the gap between design engineering and quality inspection?

Talk to ou experts and learn mor about the numerous possibilities of quality inspection with Siemens NX.

Compatible with the Technical Elements of the TE Toolbox

![]()

Unique IDs for each inspection features of a Technical Element.

The modules of the InspectionReportSuite recognize the technical elements of the TE toolbox. This preserves the semantic coherence of the PMI of a TE. The result is consistent identification of the TEs and their associated inspection features.

Direct Interface

for NX CMM

With the InspectionReportSuite, you transfer your inspection features directly to NX CMM. At the push of a button, the software extracts critical PMI from the 3D model and populates the inspection navigator fully automatically. If necessary, all general measuring tolerances can be assigned to the non-tolerated inspection features as well. This closes the gap between design and measuring machine programming. A consistent and error-free process chain is created.

Due to the standardized process and the consistent identification of the inspection features across revisions, the time to create first article inspection reports is reduced by over 70%.

More Highlights of the InspectionReportSuite

Balloon Style

The modules of the InspectionReportSuite allow you to adapt the balloon colors and shapes to your company-specific requirements. Ideal for compliance with custoner requirements (e.g. for VDA).

General Tolerance

General tolerances are stored in the software in the form of company-specific tolerance tables. These are automatically assigned to the dimensions.

External Storage

Inspection information is stored in an external project file. This achieves a clear separation between the NX part file and the quality specific inspection information.

140 satisfied customers are already trusting us

Demo. Analysis. Ideation.

Visit our webinars on quality management with Siemens NX. We appreciate your registration.

Frequently Asked Questions (FAQs)

How fast can we expect time savings and a return on invest?

The benefits of the software are immediately apparent after the implementation is complete. Inspection characteristics are automatically marked and transferred to the subsequent processes without errors. The extent of the cost savings depends largely on the status quo before the software was implemented. With manual approaches, time and cost savings of up to 90% can be achieved.

Which licensing models are available?

We offer both named user and floating license models for the interactive modules. Server licenses are provided for operating the software in batch mode.

How much user training is necessary upfront?

Depending on the implementation, the effort involved in training varies. No user training is provided for fully automatic operation of the software in batch mode. User training courses of around 2 hours are planned for interactive operation. The training period is generally very short, so that a high level of productivity can be achieved very quickly.

Do you also offer a profitability analysis before introducing the software?

Yes. We would be happy to put your current process to the test and make our results available to you for your ROI analysis. This allows you to determine the profitability of the investment in advance.

Do you support other PDM systems besides Teamcenter and SAP ECTR?

Generally speaking, yes. While standard communication modules can be used for Teamcenter and SAP ECTR, integration into other PDM systems must be implemented on a project-specific basis. Just talk to us.

Can we add our company specific general tolerances to the software?

Yes. All standards are subject to configuration.

Which output formats are available for the inspection features?

The modules of the InspectionReportSuite have a flexible and configurable output interface. This interface enables the inspection features to be exported in formats such as Excel, PDF, XML, CSV and Q-DAS. These formats are used for further use in CAQ systems or other systems along the subsequent processes.

![]()

Want to learn more about Quality Inspection?

Arrange a quick meeting or a demo today.