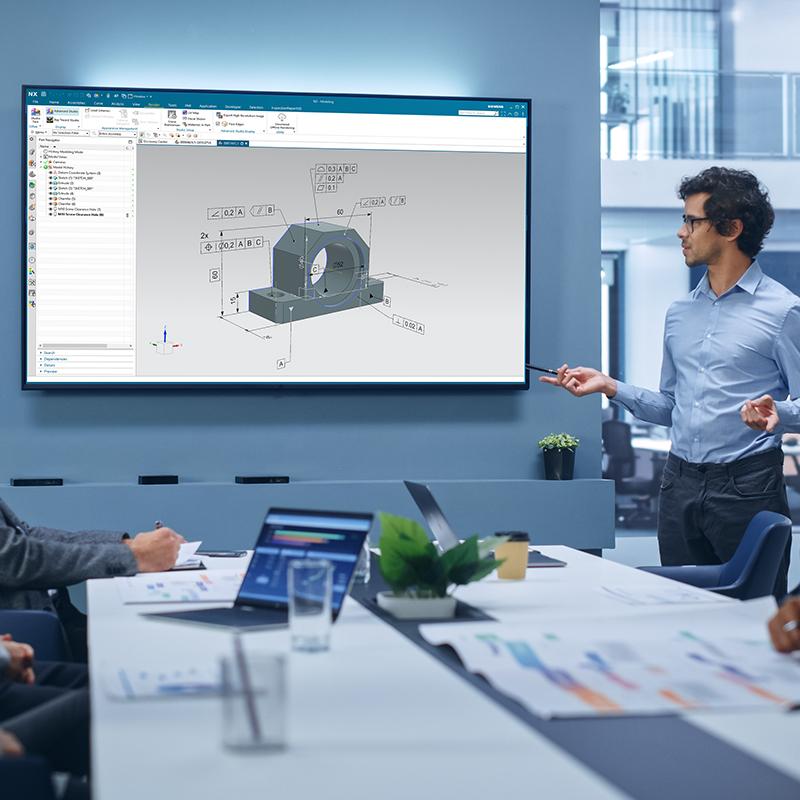

Model-Based Definition

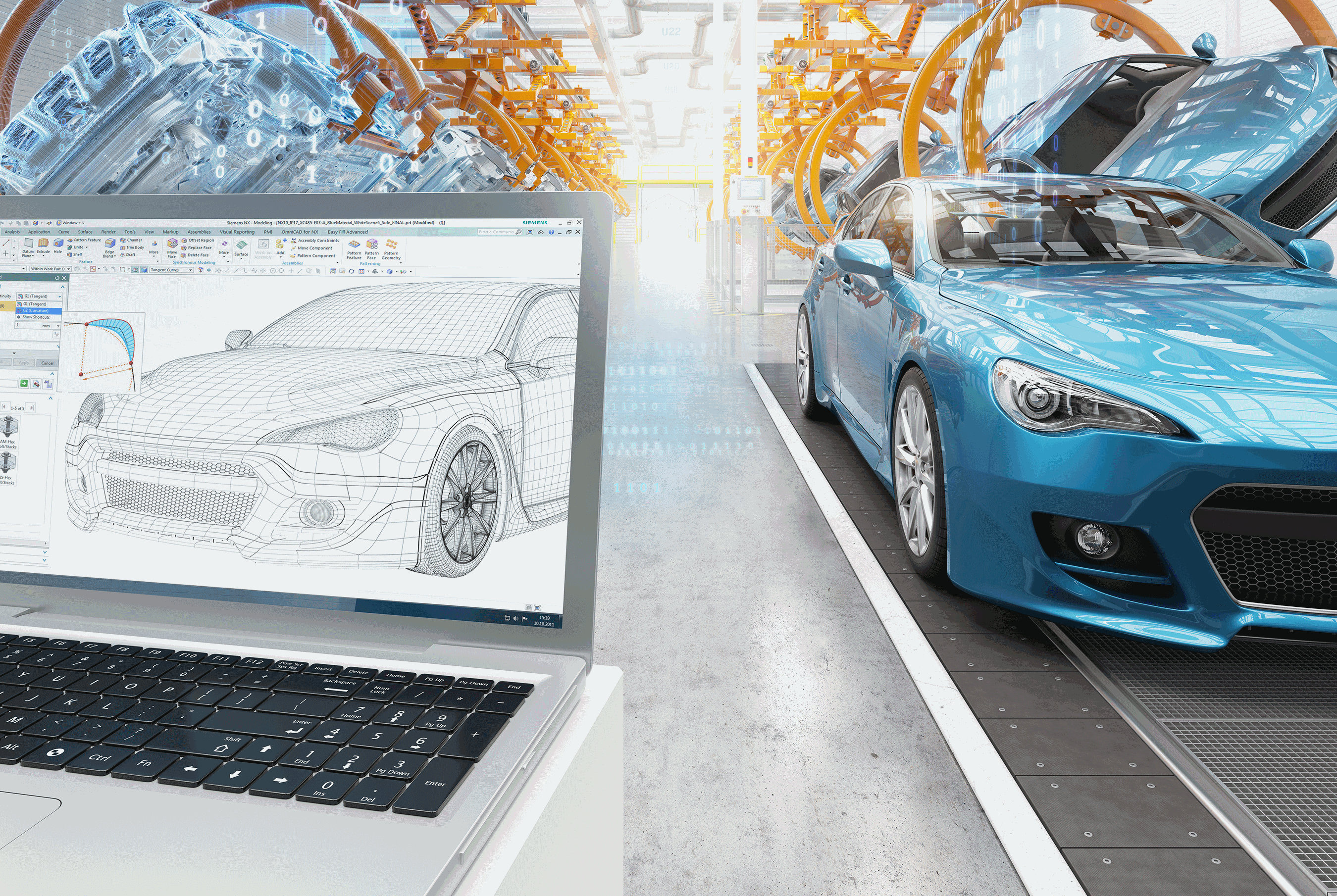

Enabling technology for the digital twin and digital manufacturing.

neoapps | Themes

Technical drawings have been firmly established in design and development for many years. The individual part or assembly for production, measurement technology or assembly is specified on them. External suppliers are also usually commissioned by exchanging technical drawings in 2D format. The central problem that arises is obvious: there are numerous media breaks along the entire development process. On the one hand, these media breaks lead to numerous sources of error along the entire value chain. On the other hand, additional manual work leads to long throughput and product development times. This is exactly where the concept of Model-Based Definition comes into play.

What is Model-Based Definition?

Model-Based Definition is a design approach or an engineering concept that focuses on the 3D model. The entire product is defined directly in the 3D model for the subsequent processes.

Example:

The 3D model thus becomes the “single source of truth” and thus the central basis for the entire product development process. All subsequent processes are based on one and the same model. This avoids ambiguities. The communication and data exchange with the suppliers should also ideally take place via a 3D model in a universally readable neutral format such as JT. As a result, technical drawings become obsolete and a drawingless production becomes a reality.

The Benefits of Model-Based Definition

reduce lead time

MBD saves a lot of time along the entire process chain. This allows you to bring new and innovative products to market faster.

reduce errors

MBD reduces the need for manual rework in each department in the downstream process chain. This reduces errors down to a minimum.

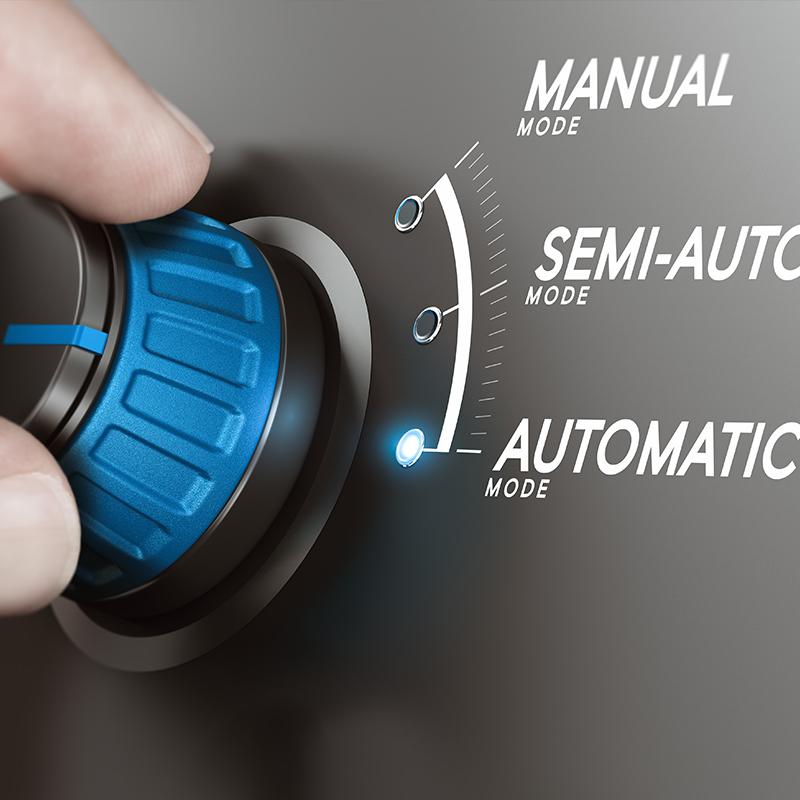

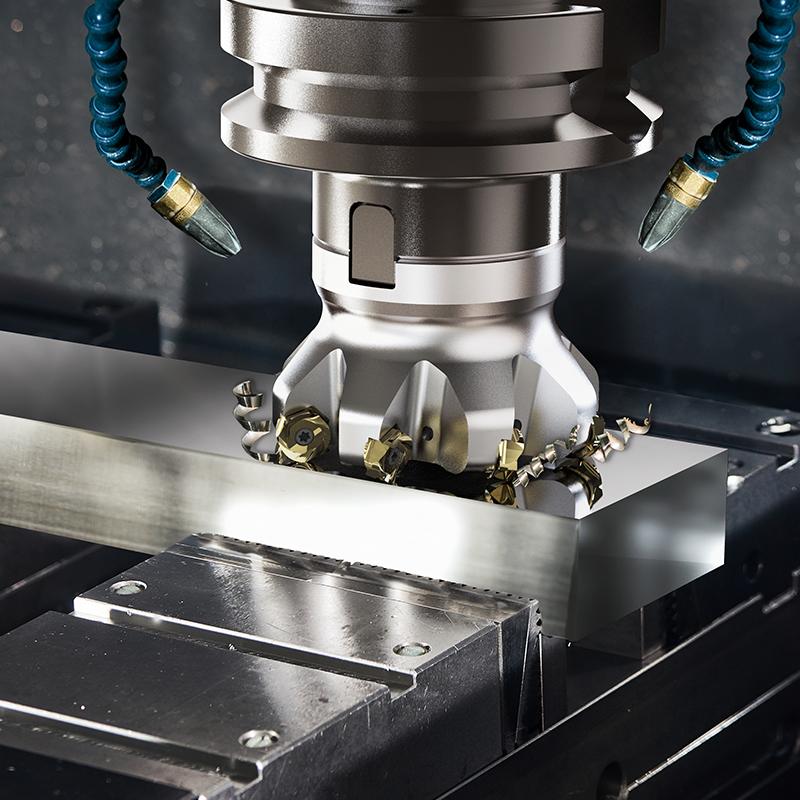

improve automation

With MBD you create a consumable 3D model in NX. This allows subsequent processes to be automated without media breaks.

Model-Based Definition not only shortens the product development time, but also qualitatively improves the entire process chain from design through production to quality assurance.

David Manita

neoapps, MBD-Consultant

Which MBD-Features does Siemens NX provide?

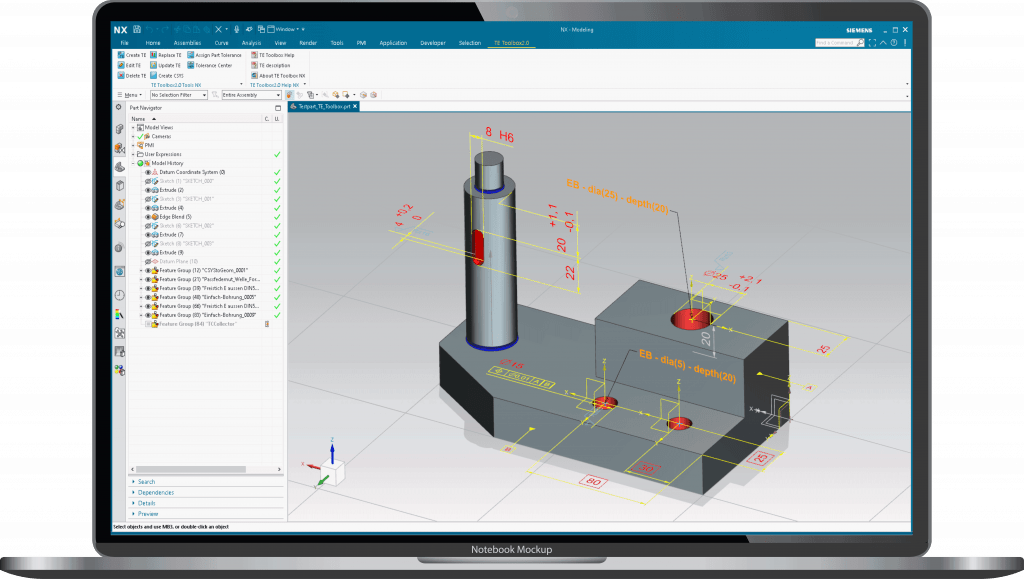

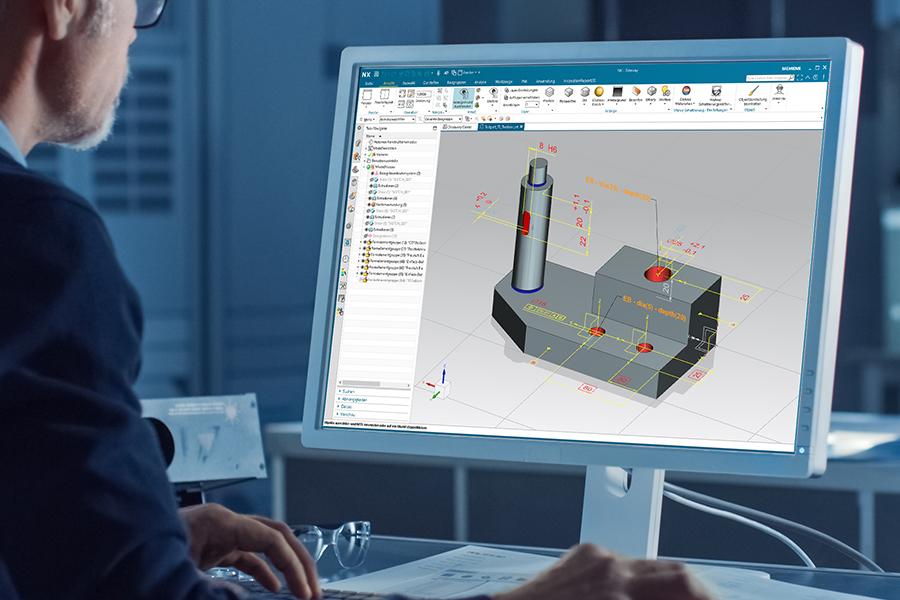

NX PMI

Basic Technology for Siemens NX

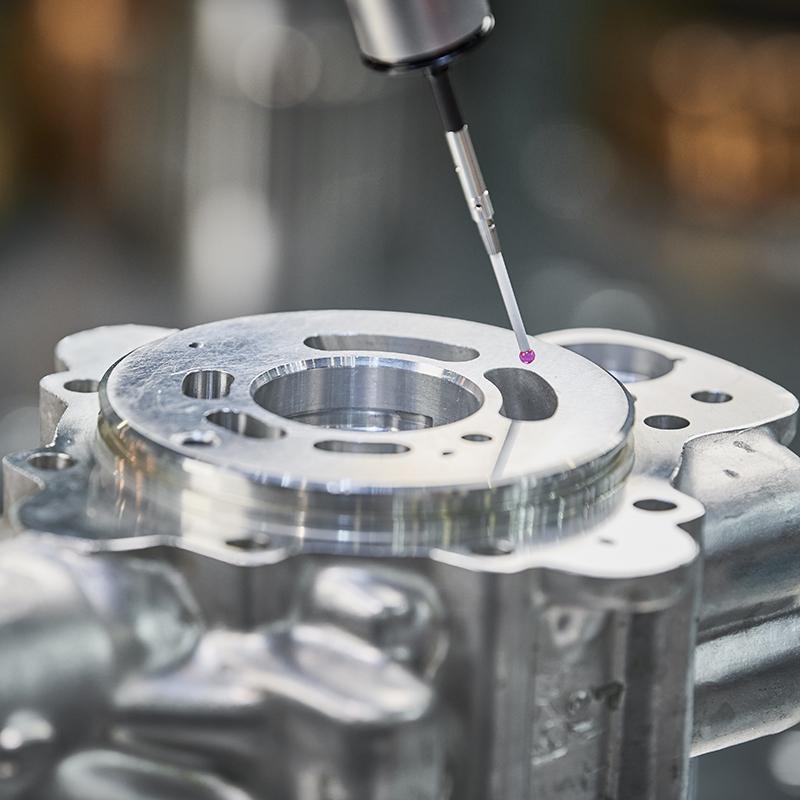

NX PMI stands for Product Manufacturing Information and is the basic technology for Model-Based Definition in Siemens NX. With NX PMI you specify a part or an assembly directly in the 3D model. This concerns, among other things, the geometric design, the surface finish or the shape and position of design features in the model. Faces and edges of the model are directly connected to the PMI via associative objects. This lays the foundation for the automation of the various subsequent processes such as CAM or CMM.

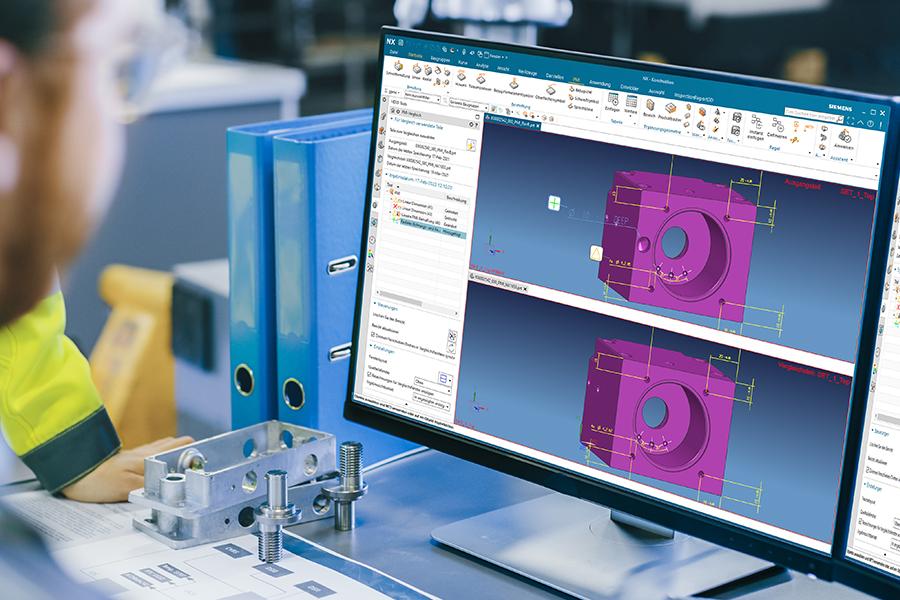

NX PMI Compare

Track design changes in Siemens NX

With the PMI comparison for Siemens NX, revision levels of two models can be quickly compared in a managed mode. The changes are displayed directly in NX and can relate to both geometry and PMI. Additional PMI object properties such as the measurement method or the properties of GD&T can also be displayed as a change. All changes are displayed visually directly in the NX and listed in tabular form in the HD3D navigator. With the PMI comparison, you significantly reduce the review time of PMI and model views.

NX PMI Advisor

Automated PMI Validation in Siemens NX

With the help of the NX PMI Advisor, you can validate your PMI in the 3D model at the push of a button. This allows you to check the PMI for compliance with the industry. or company-specific design guidelines and thus ensure more standardization of your models. The PMI Advisor is flexibly configurable to reflect customer-specific requirements. Among other things, the error messages and error levels can be individually configured. With the PMI Advisor, you transfer the know-how of highly qualified GD&T experts into a generally accessible set of rules in construction.

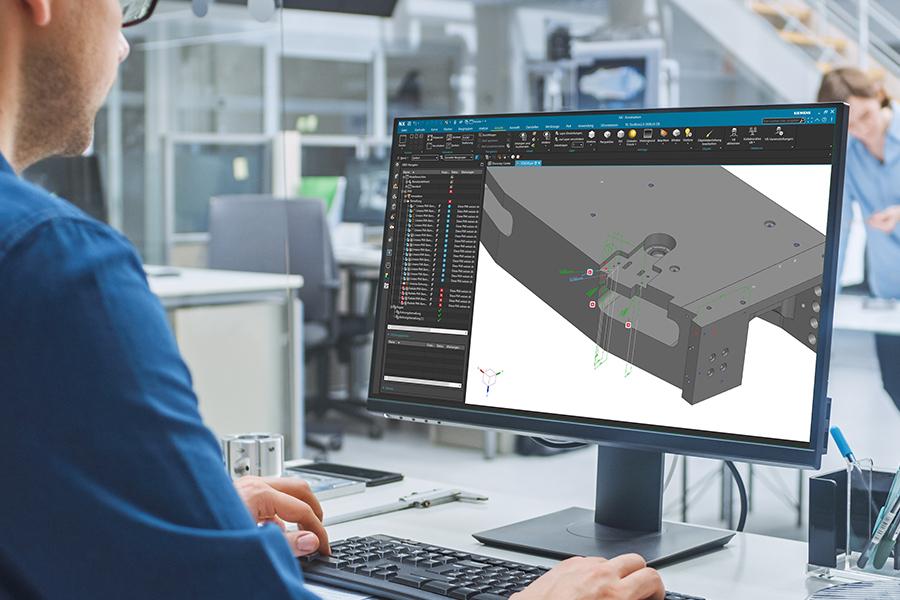

NX Logik Editor

Framework for Logical Rules for PMI in Siemens NX

With the NX logic editor, you can generate PMI at the push of a button based on user-defined rules. This way, you accelerate working with PMI in Siemens NX and thus realize further productivity gains in the preparation of the 3D model for downstream processes. The logic editor represents an interactive diagram interface that can be operated without programming knowledge. By inserting a logical rules in NX you establish a high degree of standardization of the 3D model.

All rules are managed in the NX Reuse library.

Differences between MBD and MBE

MBD stands for Model-Based Definition and describes the practice of completely capturing and defining a product in a 3D model. This includes the geometry, the PMI as well as the metadata.

MBE stands for Model-Based Enterprise and describes the process of reusing the fully specified 3D model in the subsequent processes of the downstream departments.

Implementation of MBD

For most companies, the introduction or implementation of MBD is accompanied by a fundamental change in development processes. For this reason, careful preparation of an MBD project is of paramount importance. Some of the steps to consider include:

- Interdisciplinary project management: the transition from a conventional design approach to a model-based definition approach does not only effect the design. Rather, the entire process chain of product development is subject to a fundamental change. Model-based definition is multidisciplinary and thus affects all departments. Ideally, even the suppply chain should be involved. For this reason, the willingness to change on the part of all parties involved as well as a interdisciplinary project management are essential for a successful implementation of model-based definition in the organisation.

- Begin with the end in mind: Mode-Based Definition is not an end itself. The opposite is true: Metadata in the 3D models only serve as a means to an end. They are vicarious agents in achieving various goals in the subsequent departments. So it is the design methods in the subsequent processes such as manufacturing or quality that determine the applicable standards in mode-based definition. What attributes are required in NX CAM? Which GD&T does the measuring machine program consume?

- Legacy Data: Model-Based Definition rarely starts in a green field environment. For this reason, the handling of legacy data is one of the most important aspects in the course of an implementation project.

- MBD training concept: The introduction of model-based definition requires a paradigm shift of your emplyees along the entire process chain. Technical 2D drawings are no longer required. Instead 3D models are reused throughout the process chain. This is accompanied by a wide range of new tools and processes that require extensive training. A proper training concept is therefore essential for a successful implementation of MBD.

MBD as the cornerstone of the digital twin

The virtual representation of a physical product or process requires MBD

Building a digital twin takes your entire engineering to a new level. They simulate both the properties and behavior of the end product and the entire manufacturing process. And that even before the product or the process physically appears. In a way, Model-Based Definition is the “enabler” of the digital twin by completely capturing the product and all process information in the 3D model.

The importance of metadata for MBD

Metadaten als Grundstein zur Automatisieren Ihre Folgeprozesse

Metadata is essential in order to be able to consume 3D models in the subsequent processes consistently and without additional manual effort. The following metadata are critical:

- PMI

- Attributes

- Color

- Names

With the help of this metadata, you can automate your follow-up processes throughout.

Can I bring metadata into my 3D model in an automated fashion?

Yes. With Technical Elements of the TE Toolbox for Siemens NX

Our MBD services for you:

MBD Consulting

Conception and Analysis

We advise you comprehensively on the subject of MBD. From the analysis to the conception to the suitable tool selection, we provide you with our know-how on the subject of model-based definition.

Our MBD-solutions for you:

TE-Toolbox

MBD with Technical Elements in NX.

Model-Based Definition starts with a standardized CAD model. Technical elements guarantee you compliance with all valid guidelines in the design. This means that all meta information is created in themodel right from the start in 3D.

![]()

Questions on the topic of MBD?

Talk to our experts and learn more about the wide range of possibilities with model-based definition.