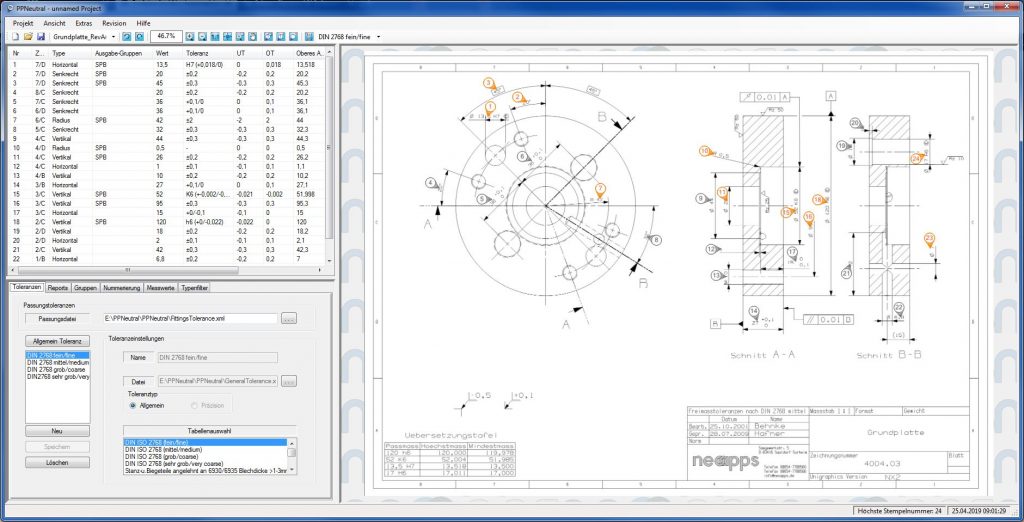

Inspection Report Neutral – initial sample inspection reports for neutral formats

Using Inspection Report Neutral can help you achieve time savings of up to 70% in the creation of initial sample inspection reports and stamped Q drawings and therefore reduce your quality department costs. The automated process also reduces data errors when creating test reports. Inspection Report Neutral manages the creation of initial sample test reports for you by assigning the correct test numbers to the desired features, such as measurements, GD&Ts or texts. Then, at the touch of a button, you can create an initial sample inspection report in any format (e.g. Excel, PDF, QDAS etc.) with the corresponding Q drawing.

The display of the test tables is fully configurable in order to meet your precise requirements.

An overview of the advantages for you

- Time savings of up to 70% when creating PPAP documents

- Increased readability and clarity of the stamped technical drawings and initial sample inspection reports

- Improvement in the quality of the products that you manufacture

- Clear labelling of all features for improved communication with both internal and external stakeholders

- High level of automation thanks to OCR recognition

- Supports numerous neutral formats, such as TIFF, PDF, PNG etc.

- Management of the testing documents in a central PLM system

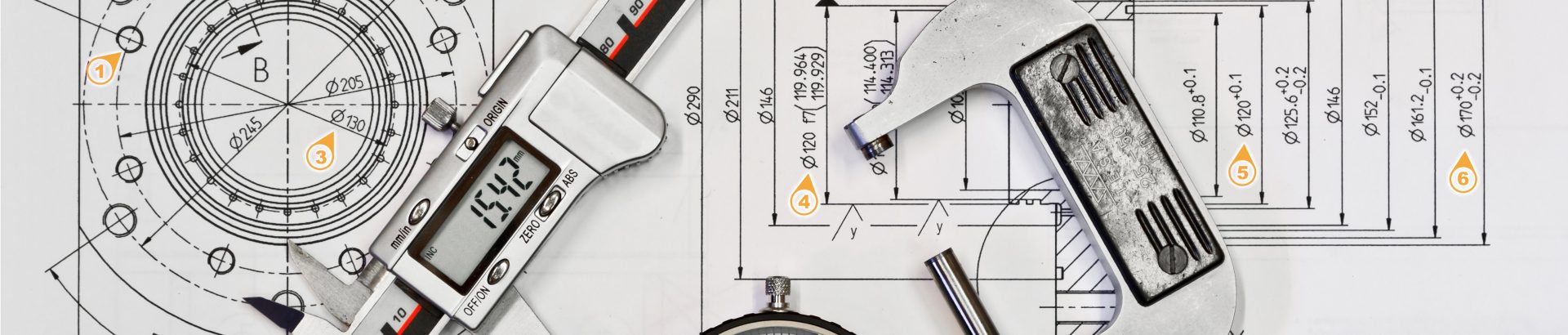

Modern inspection plan creation independent of CAD

You can process all commonly-used neutral formats, such as TIFF, PDF, PNG etc., with Inspection Report Neutral. This means that your drawing can be stamped independently of the CAD creation system on a Windows PC. This means that no CAD licences are required, which saves quality department costs.

Faster feature transfer and error prevention

Thanks to a sophisticated text recognition algorithm (OCR), all nominal dimensions, tolerances, notes, GD&T and similar are recognised automatically and included in the Inspection Report Neutral. The values are included next to the feature in the test table directly after the stamp has been positioned. This not only means that you can significantly increase the speed of feature transfer but also that you can avoid data errors at the same time. Inspection Report Neutral therefore also improves the reliability of test plan creation by improving data consistency.

Connectivity options

In order to make the features that are relevant to quality accessible on a company-wide basis, Inspection Report has a very flexible interface that you can use to connect a broad range of PLM, CAQ and other target systems. Here is an extract of the most common systems:

- Teamcenter

- SAP PLM with ECTR

- CASQ-it by Böhme & Weihs

- PiWeb by Zeiss

- Calypso by Zeiss

- etc.

Communication with the target systems takes place either directly between a target system and the API provided or via exchange formats, such as ASCII or XML. This means that there are few limitations with regard to the transfer and distribution of information that is relevant to quality, whereby a stable and consistent process is ensured.

Get productive quickly thanks to minimal learning time

Thanks to its intuitive user interface, Inspection Report Neutral is easy and quick for you to use. This means that extended learning times are not required. This enables you to make further cost savings when implementing software-supported inspection report creation.

Using the connection to the PDM system, you can check out and stamp your drawings and check them back into the PDM system with a click.

Different test lots by grouping features

The software provides you with the option of grouping features so that you can create different test tables. For example, this enables you to create different test documents for different suppliers. You can also product series test reports or initial sample test reports, including the corresponding stamped drawing, at no extra cost.

Automatic assignment of tolerances

You can save extra time with Inspection Report Neutral in terms of transferring tolerances into the Test Plan as all standard tables (e.g. DIN ISO 2768) in the software are already saved there. Stamping the features automatically assigns the correct tolerance to the measurement element in question independently of the nominal dimensions. This enables you not only to speed up the entire process of test report creation but also to avoid data errors when assigning tolerances.

Compatibility with Inspection Report for NX

Inspection Report Neutral is fully compatible with the other Inspection Report Suite modules. Like in Inspection Report for NX, Inspection Report Neutral places all stamp information in external XML storage. Stamped documents can therefore be exchanged between Inspection Report for NX and Inspection Report Neutral without any problems. This means that it is possible to start stamping in Inspection Report for NX at the construction stage and continue with Inspection Report Neutral at the quality management or incoming goods stage.

Inspection Report Neutral can also be licensed and used as a cost-effective viewer. This enables you to view NX drawings stamped at the construction stage in other departments, for example the incoming goods or quality management departments. This means you do not need additional CAD licences.

The viewer functionality is also the perfect tool for exchanging project data with your suppliers. You can use Inspection Report Neutral to export entire projects as your own project file.

You can provide this to your supplier, who can then use the viewer to look at the entire project.

You can find out more about NX data stamping here.

Contact

If you are interested in a company-specific custom development and would like to find out more, please feel free to get in touch with us.

Give us a call on: +49 (0) 86 54 / 77 88 56-0

or send an email to: info@neoapps.de

Alternatively, you can fill out our contact form here. We look forward to hearing from you.